Description

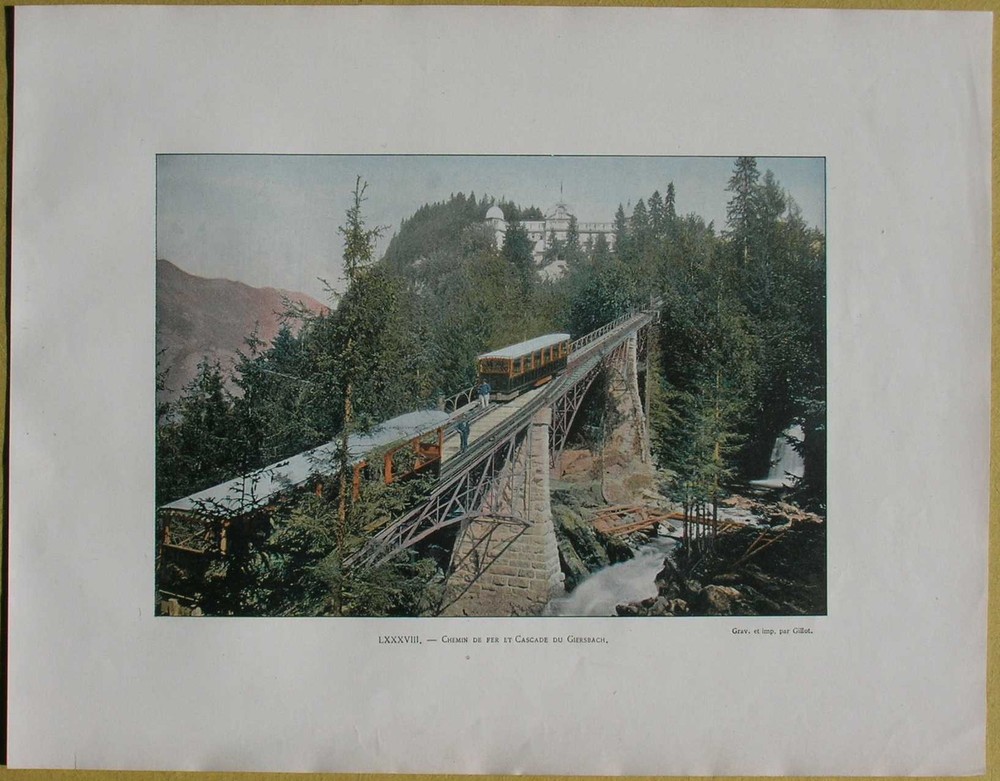

Boulanger_088 ca.1895 French photochrom SWITZERLAND: RAILWAY AND CASCADE OF GIESSBACH (#88) Photochrom titled Chemin de fer et cascade du Giersbach, page size 32 x 24 cm, image size 21 x 14.5 cm. From: Autour du Monde - Aquarelles - Souvenirs de Voyages, Paris, L. Boulanger, editeur. Click image or here to view larger version Giessbachbahn The Giessbachbahn (GbB, English: Giessbach Funicular) is a historic funicular in the Swiss canton of Bern and municipality of Brienz. It links a landing stage on Lake Brienz, served by shipping services on the lake, to the Grand Hotel Giessbach and Giessbach Falls above. The funicular is owned by the hotel, but since 1983 has been operated by a preservation foundation. The Giessbachbahn was designed by the Swiss engineer Carl Roman Abt. When it was opened in 1879, it was the first funicular with a two-rail single track layout with a short passing loop in the middle. Its turnouts, in common with other similar funiculars had no moving parts. Abt had later developed its modification which became known as the Abt Switch. Originally the funicular was powered by water ballast, and the Riggenbach rack rail in the middle of the track was used for speed control. In 1912 the water ballast system was replaced by a hydraulic engine powered by a Pelton turbine. Which is in its own turn was replaced in 1948 by an electric drive. The rack rail is currently used for emergency braking. The funicular's two wooden cars are restored back to their original appearance in 1879. In 2015 the funicular was included in the list of Historic Mechanical Engineering Landmarks by the American Society of Mechanical Engineers under number 259. Photochrom Photochrom (also called the Aäc process) prints are colorized images produced from black-and-white photographic negatives via the direct photographic transfer of a negative onto lithographic printing plates. The process is properly considered a photographic variant of chromolithography, a broader term referring to color lithography in general. History The process was invented in the 1880s by Hans Jakob Schmid (1856–1924), an employee of the Swiss company Orell Gessner Füssli, a printing firm with a history extending back into the 16th century. Füssli founded the stock company Photochrom Zürich (later Photoglob Zürich AG) as the business vehicle for the commercial exploitation of the process and both Füssli and Photoglob continue to exist today. From the mid 1890s on the process was licensed by other companies including the Detroit Photographic Company in the US and the Photochrom Company of London. The photochrom process was most popular in the 1890s, when true color photography was first being developed but was still commercially impractical. In 1898 the US Congress passed the Private Mailing Card Act which allowed private publishers to produce postcards. These could be mailed for one cent each — the letter rate at the time was two cents. Thousands of photochrom prints, usually of cities or landscapes, were created and sold as postcards and it is in this format that photochrom reproductions became most popular. The Detroit Photographic Company reportedly produced as many as seven million photochrom prints in some years, and ten to thirty thousand different views were offered. After World War One, which brought an end to the craze for collecting Photochrom postcards, the chief use of the process was printing posters and art reproductions, and the last Photochrom printer operated up to 1970. Process A tablet of lithographic limestone, known as a "litho stone," is coated with a light-sensitive coating, comprising a thin layer of purified bitumen dissolved in benzene. A reversed half-tone negative is then pressed against the coating and exposed to daylight for a period of 10 to 30 minutes in summer, up to several hours in winter. The image on the negative allows varying amounts of light to fall on different areas of the coating, causing the bitumen to harden and become resistant to normal solvents in proportion to the amount of light that falls on it. The coating is then washed in turpentine solutions to remove the unhardened bitumen and retouched in the tonal scale of the chosen color to strengthen or soften the tones as required. Each tint is applied using a separate stone bearing the appropriate retouched image. The finished print is produced using at least six, but more commonly from 10 to 15, tint stones.